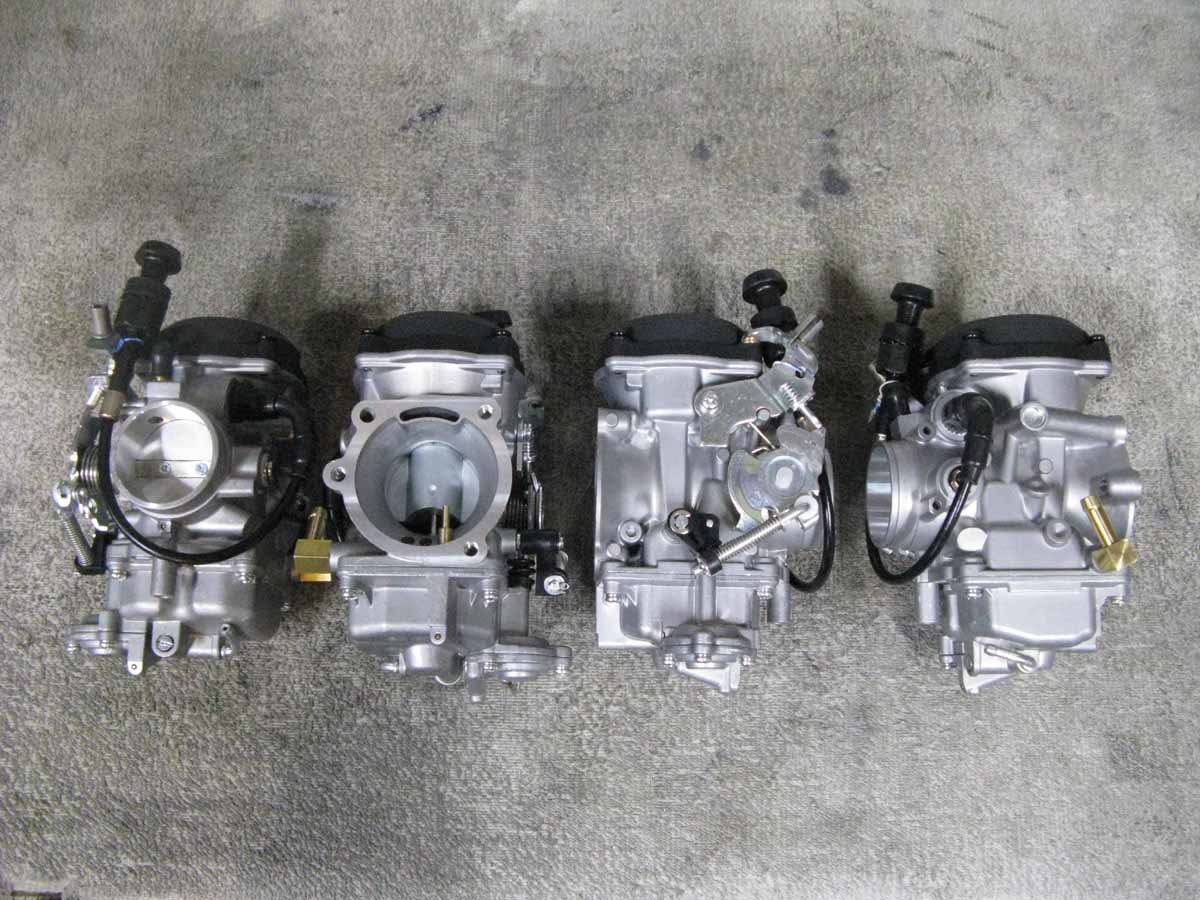

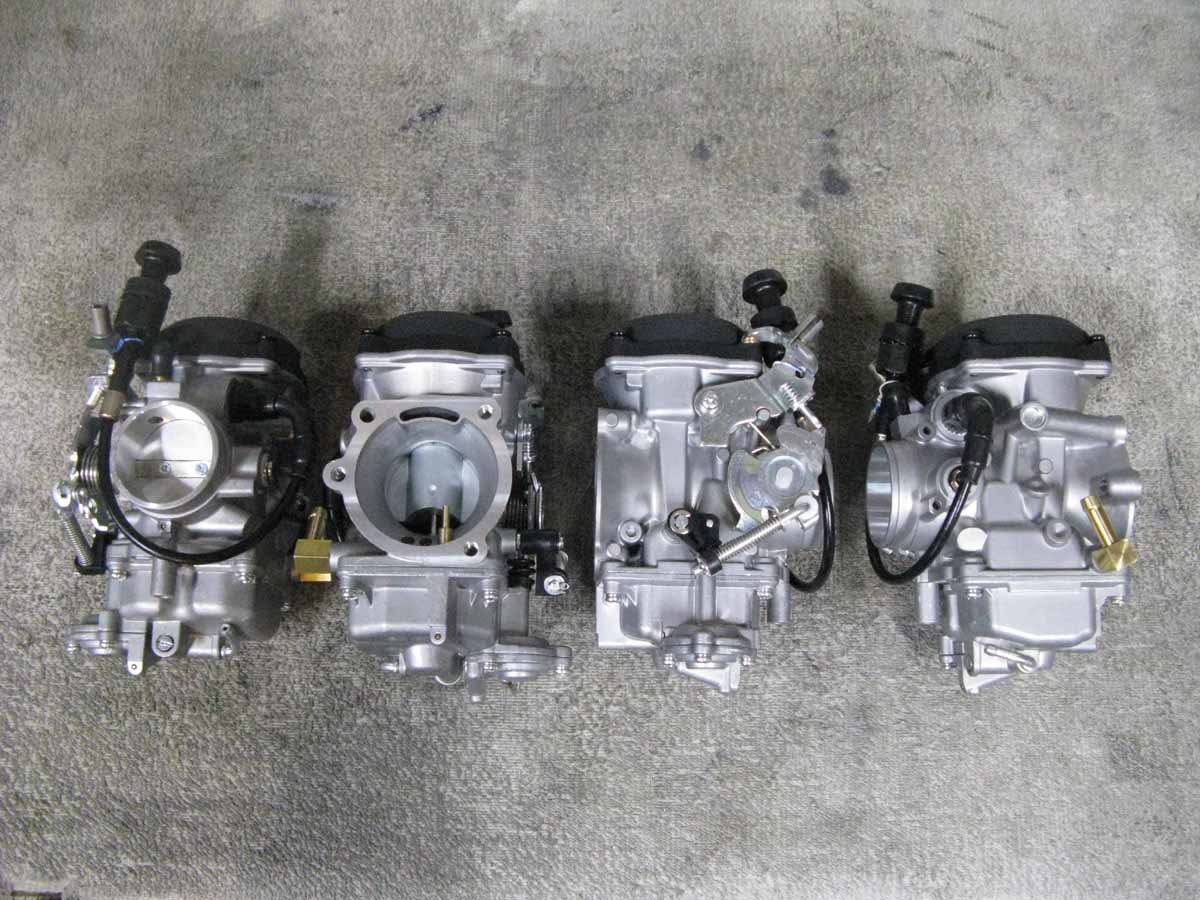

Chinese Replica CV40 carbs

Some Problems With the New Chinese Replica CV40 carbs

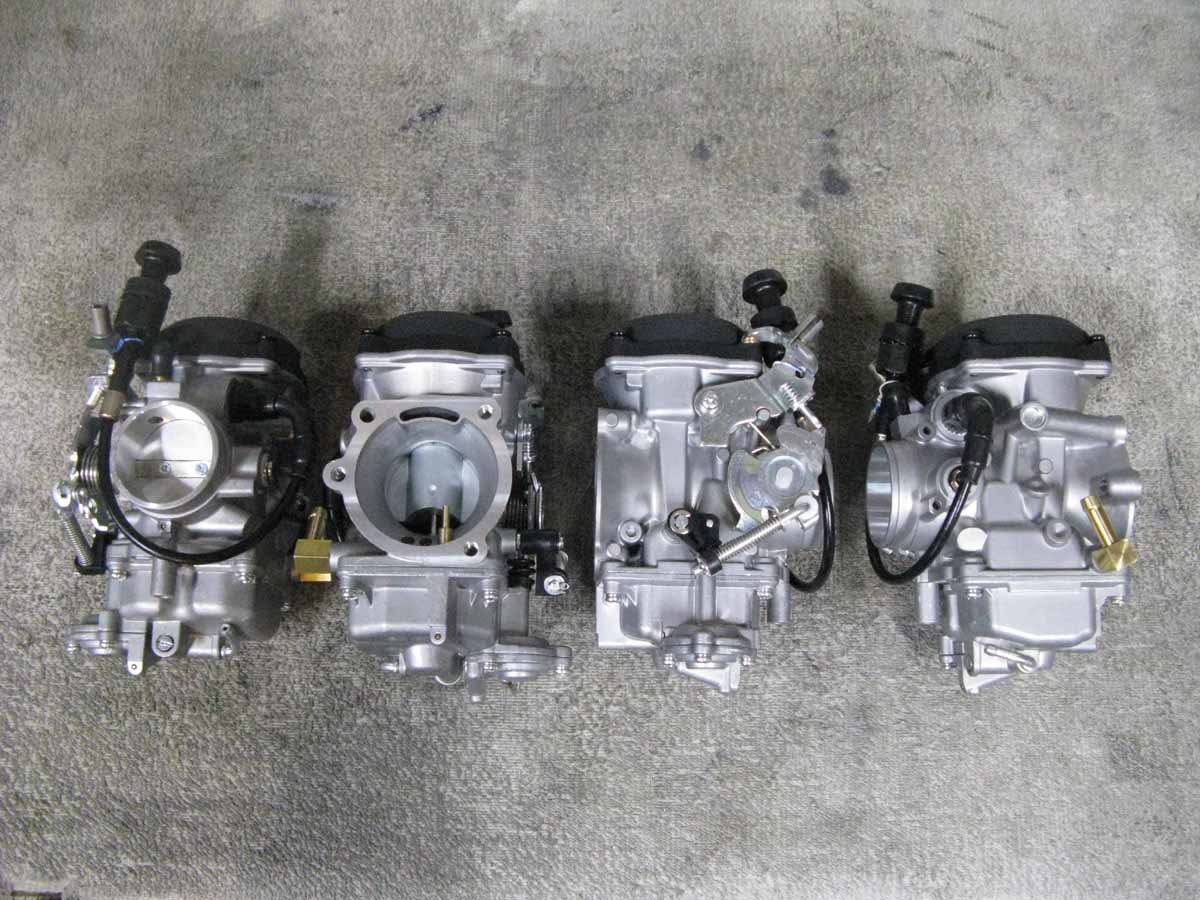

Since the supply of original rebuildable Keihin CV40 carbs has pretty much dried up, it is a welcome thing that the Chinese are reproducing them. I have bought a few from different sources, and I believe that there is one central source there that has purchased the tooling from Keihin in Japan, and they are mass producing them. I have really disected them, and they are exact copies. But, there are a few tweaks, and one major problem that I hope they fix. We'll start with the easy fixes. First, on the throttle linkage, where the .250" diameter cable barrel drops in, sometimes it won't go in, and I use a Dremmel with a 1/8" Carbide burr to open the hole very slightly (just where the barrel will drop in). Next, the jet kit requires replacing, because it is an inaccurate jet kit, that's never going to work. For Indian Chiefs, you must use the Yost "Power Tube" jet kit for best performance. Next, the float setting, and mixture settings need to be corrected.

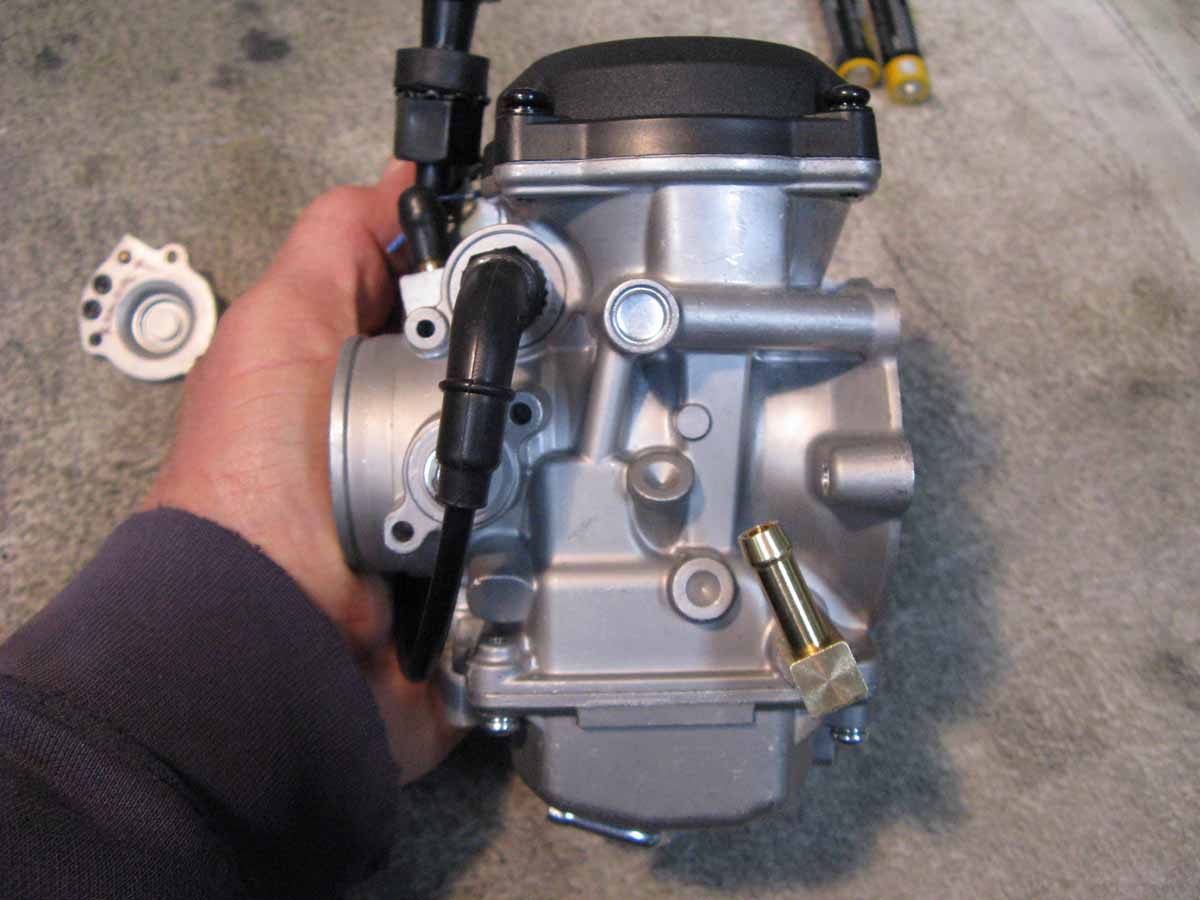

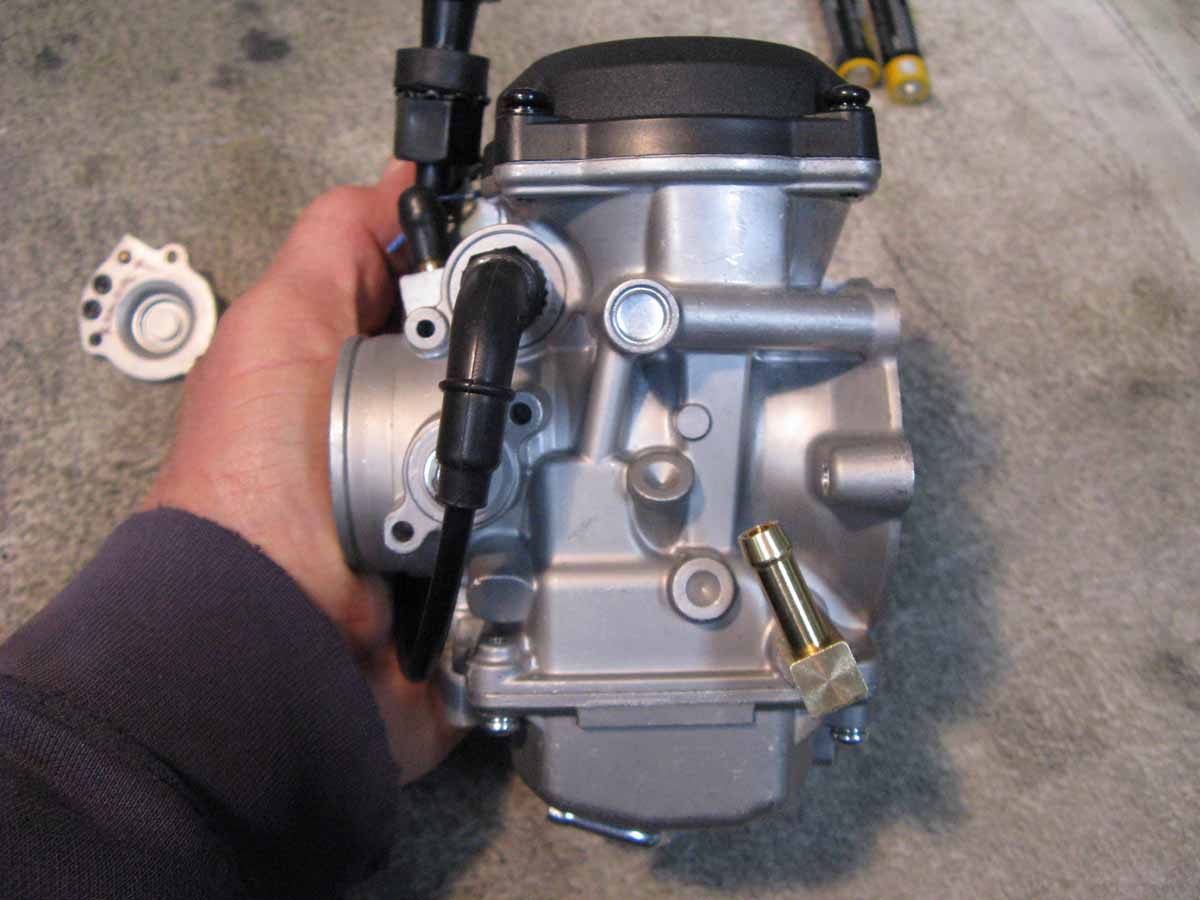

The next fix has to do with the fuel inlet. Like all original CV's, the fuel inlet needs to point directly at a pressed-in 3/8" dia. plug found about 1" to the right of the choke cable on the left side of the carb. After heating the area with a Propane torch for at least 5 minutes, you can grab the brass fitting with a 10mm open wrench, and twist it hard. It needs to be heated in the casting near the fitting, both inside the bowl, and outside. So, the bowl must be removed for access, and the float needs to be removed by pushing out the pivot pin, and removing the float with the needle intact. Re-assemble the float, needle, and bowl. Don't forget the pump rod!

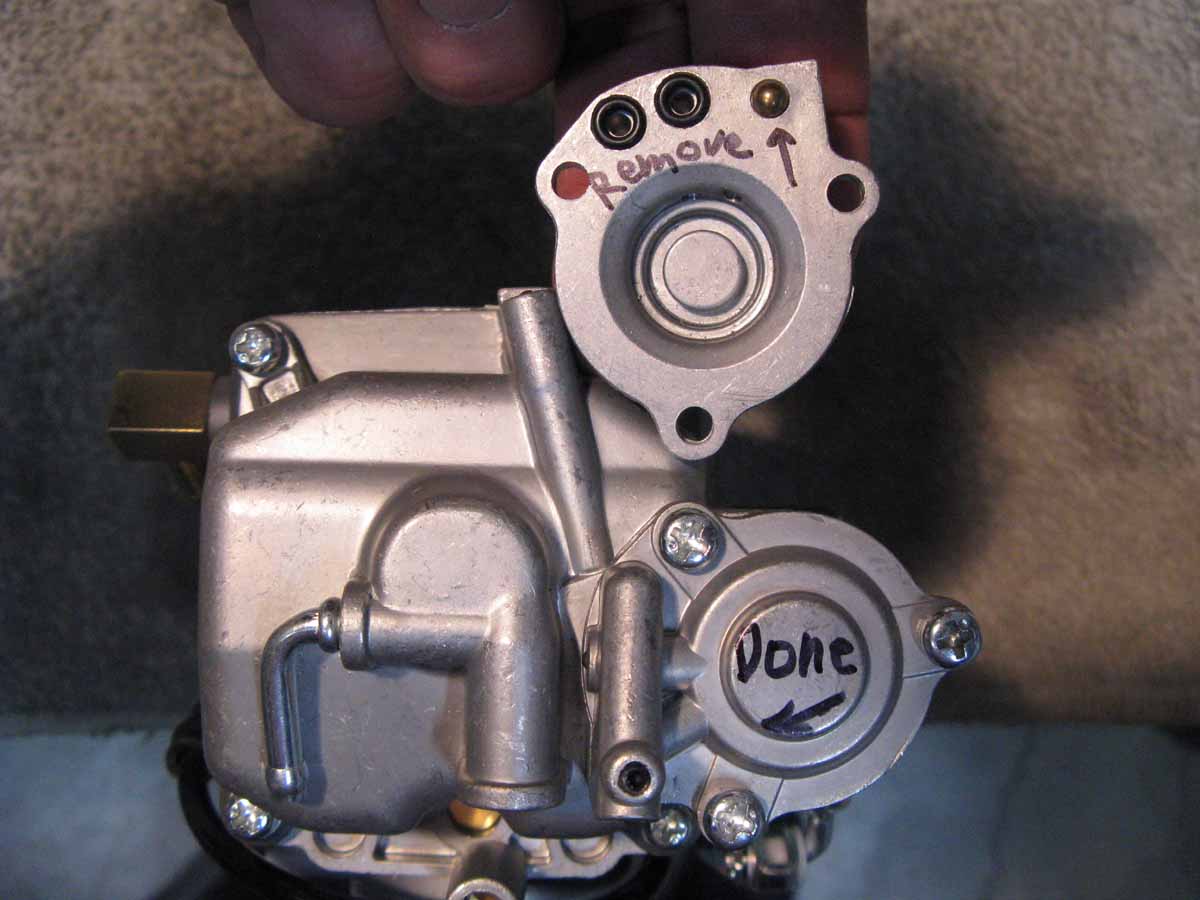

The next fix has to do with the vacuum slide. I assume that the CV40 Replica factory picked some unknown jet kit to copy, and I wouldn't even try to make it work, considering that the Yost "Power Tube" does such a fine job for Indian Chiefs. In all cases, jet kit providers ask to have the slide's vacuum hole to be enlarged. That's OK for Harley-Davidsons, but not for Indians. I found it best to use the stiffer Yost spring (or factory H-D), and to drill out the vacuum hole with a .106" (number 36) drill. This will open the hole to .110" (stock is .093"). These Chinese Replica CV40 carbs are drilled out to .125", which is too big. When the hole is too big, or especially with a weak spring, the slide will flutter up and down at light cruising speed loads, like 50 mph. The slide is supposed to rise and fall with throttle use, but it should be quite stable. The vacuum slide lifts the enrichment needle as throttle is applied. Too big of a vacuum hole, or too weak of a spring causes the slide to bob up and down rapidly, causing an over rich condition. So, this hole needs to be reduced. I found the best way is to Epoxy the hole up, and re-drill the hole with the .106" (#36) drill. I use "JB-Weld", which is chemical proof. I take a little piece of masking tape, and cover the hole on the outside, and I use a tiny long screw driver to take small amounts of Epoxy, and fill the hole inside the slide. You don't need to use much, and you want to completely fill the hole (no air pockets!), and leave a little to form a tiny mound of Epoxy around the hole. It will puddle, and smooth out on it's own. After it sits for 24 hours, you can drill the new hole. Make sure to clean the inside of the slide with some thinner, so the Epoxy sticks. Done!

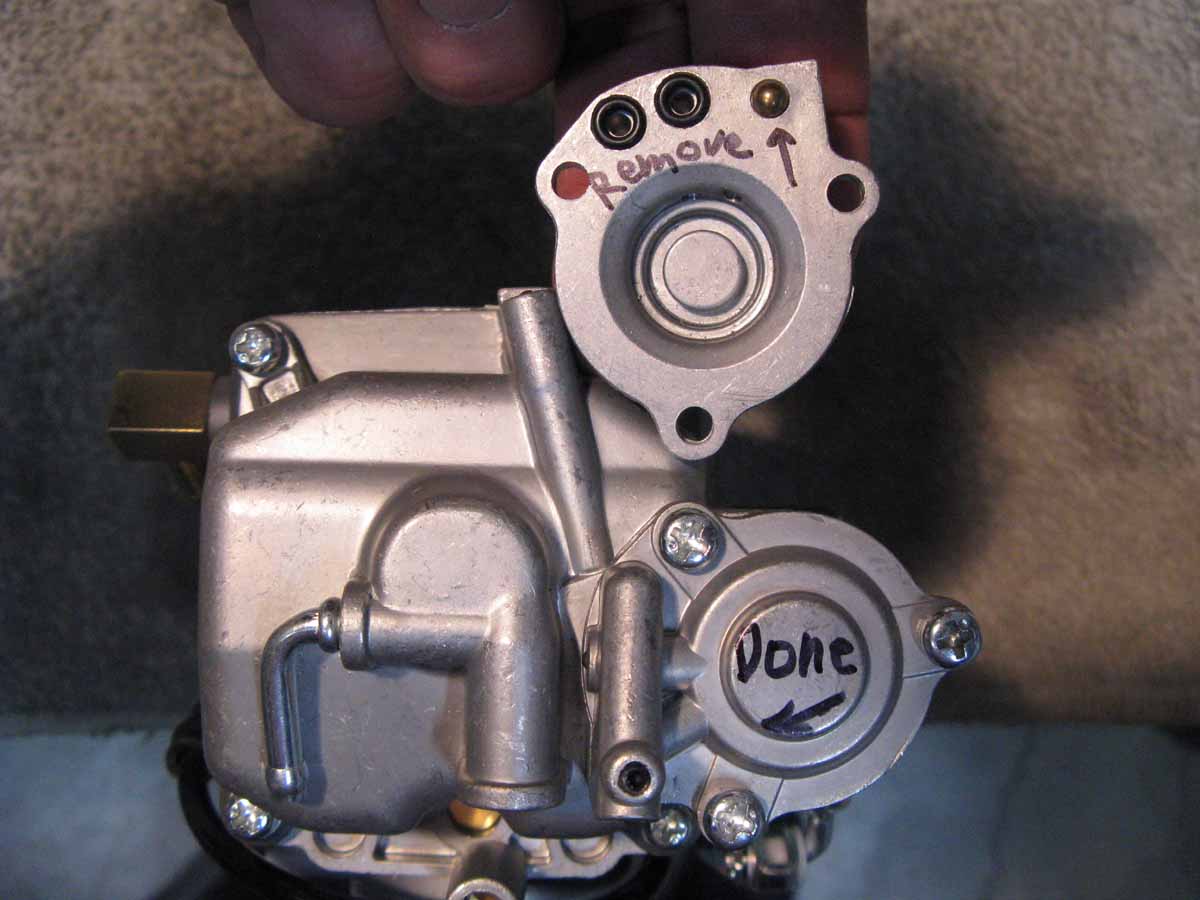

Last is the accelerator pump fix. They forgot to install a 1/8" check ball in the accelerator pump housing, so the pump moves very little fuel when operated. Oops! The easy fix is to just replace it with a new pump housing from Harley-Davidson's later model carbs (with 2 small O-rings). I know that the 2002 models, and later had the correct part. Earlier housings are different! I developed a fix, where you drill a hole into a small round raised boss below where the 1/8" ball bearing sits. This hole will be tapped for a 6-32 X 3/16" allen set screw used as a plug when finished (and green Lock-Tited in place). This hole is drilled with a .106" drill bit (for the 6-32 set screw before tapping), and should be drilled exactly 7mm deep. This is so you don't drill too deep, and wreck the surface that the ball bearing will sit on. It is very important to drill the hole in the exact center of the raised boss! In that 7mm length, you will drill past a side passage for fuel to run in. Be sure to use air to blow out any debris! Protect the surface where the ball sits! Now, use a small drill bit as a punch to knock out the brass "BB" that is pressed into the housing's underside (through the new .106" hole). Set the housing on a vise that is opened about 3/16", so the ball can fall through the gap when the ball is tapped out of it's hole. Don't lose it! It will tap back in easily after the debris is cleaned out, and the 1/8" ball bearing is dropped into the hole. But, first you need to "Stake the Hole" where the ball bearing sits. Make a tiny punch, like a nail with the end ground flat, and gently tap lightly on the ball bearing sitting on it's seat many times. This will "kind of" polish the surface where the ball sits to seal better. Drop in the ball, and knock in the brass "BB" flush. Now, install the allen set screw flush to the end with a little green Lock-Tite. Re-install the housing to the carb's bowl, and you will have much more accelerator pump response.

CONTACT INFORMATION:

James R. Mosher

1-505-466-7870